OUR TECHNOLOGY

HPP Process

High Pressure Processing (HPP) has revolutionized the avocado industry, particularly benefiting guacamole and other avocado-based products. This technology enables the production of natural, preservative-free items with an extended shelf life, making them suitable for global distribution.

Here’s how HPP enhances avocado products:

- Maintains Natural Green Color: HPP partially inactivates Polyphenol Oxidase (PPO), the enzyme that causes browning. This helps preserve the vibrant green color of guacamole.

- 100% Natural and Fresh: The cold process of HPP keeps the flavor, color, and nutrition profile of guacamole unchanged. It eliminates the need for preservatives or additives.

- Extended Shelf Life: HPP extends the shelf life of guacamole and other avocado products while maintaining their sensory characteristics.

- Enhanced Food Safety: By inactivating foodborne pathogens and spoilage microorganisms, HPP improves food safety and ensures a longer-lasting, safe product.

- Opportunities for New Products: With avocado’s growing popularity, HPP supports the development of new products such as avocado paste, halves, dips, and beverages.

- Flexible Packaging Options: HPP accommodates various packaging formats including tubs, large bags, vacuum-sealed packs, and bottles for beverages.

HPP technology continues to drive innovation and quality in the avocado sector, offering both manufacturers and consumers a reliable and fresh product experience.

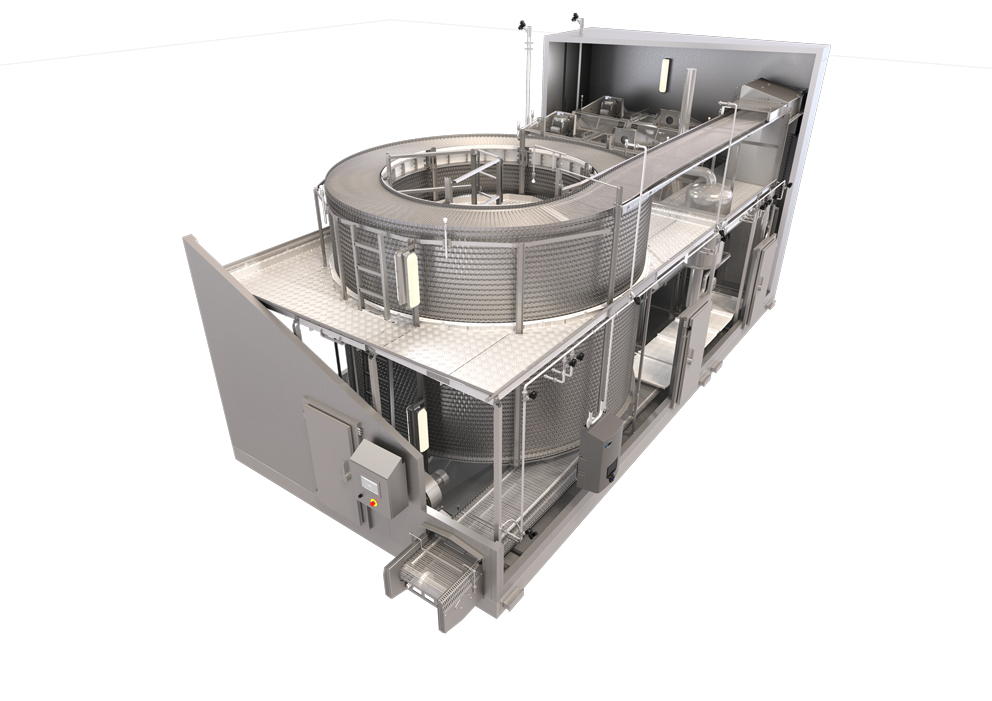

IQF Spiral Freezers

Our Spiral Freezer incorporates a highly efficient and energy-saving horizontal airflow principle, designed to deliver optimal freezing results. Here’s how it works and the benefits it provides:

- Efficient Freezing: The horizontal airflow system ensures that the product is evenly exposed to the cold air on every level, allowing for rapid and uniform freezing. This minimizes the time required to freeze the product, preserving its quality.

- Preservation of Delicate Products: The high air speed and even freezing process are particularly beneficial for delicate products such as guacamole and av0cado paste ensuring they are processed with care and maintain their quality.

- Continuous Operation: Avo-Pak’s spiral freezer is built to operate efficiently over extended periods without needing defrosting in between processing cycles. This continuous operation enhances production flexibility and reduces downtime.

- Cost Efficiency: By avoiding sequential defrost cycles, the freezer minimizes the need for electrical power, reducing overall energy costs. Additionally, it lowers expenses related to cleaning personnel, cleaning supplies, and wastewater management.

- Environment: We ensure the integrity of the cold chain from start to finish. Furthermore, we are committed to environmental protection by utilizing CO2 as our refrigerant. This natural refrigerant helps minimize environmental pollution and safeguards the ozone layer.

The Spiral Freezer offers both operational and cost advantages, ensuring that your products are frozen quickly and efficiently while maintaining high standards of quality.

Solar Technology

At Avo Pak, we recognize the crucial role of renewable energy in delivering sustainable products to our customers. That’s why we have invested in the largest solar PV array in Laceja, with a capacity of approximately 1.4 MW, installed at our processing plant. This initiative significantly reduces our carbon footprint and underscores our commitment to environmental responsibility. Our goal at Avo Pak is to provide a product to our customers that is produced with little to no impact on our environment by using recycled products and by creating our own clean energy source

GET IN TOUCH

Interested in learning more about our company and our products, please don’t hesitate to contact us so that we can customize a product for your needs.